The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTE

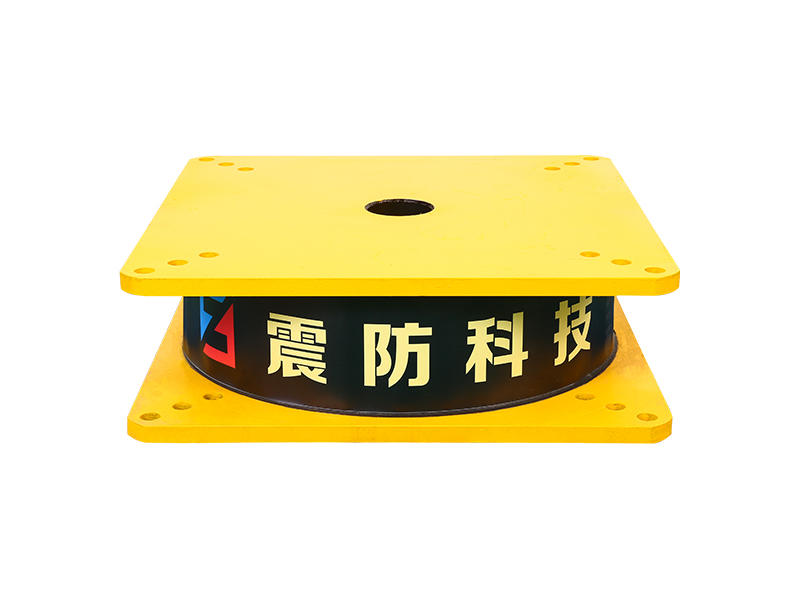

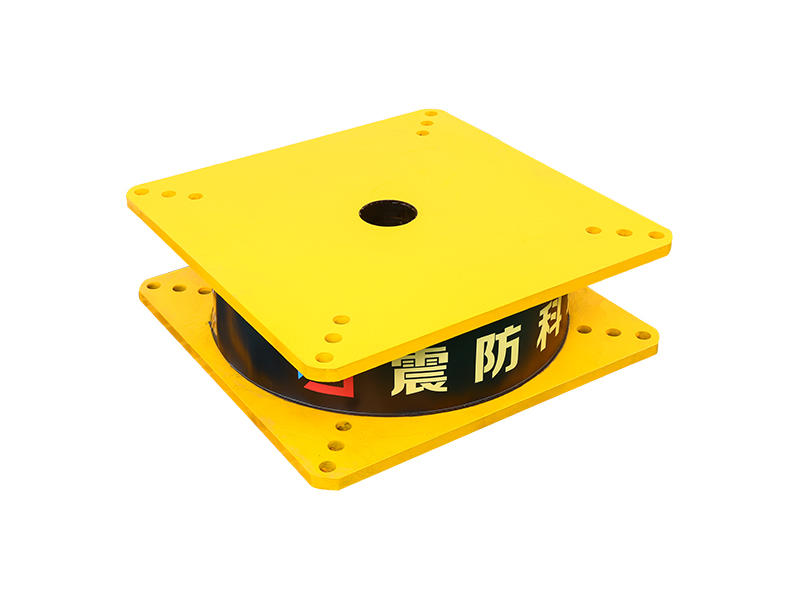

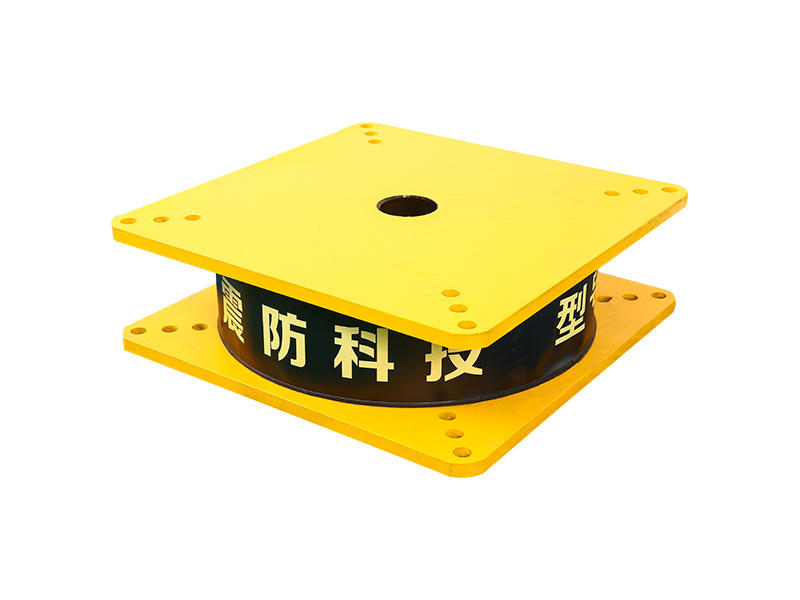

| Construction lead-core rubber bearing Ⅱ type (LRB-Ⅱ) Building natural rubber bearing Ⅱ type (LNR-Ⅱ) |

Features: Superior performance, longer life, upgraded version |

| Specification: LRB/LNR-Ⅱ type (diameter: 200~ 1500mm) | |

| Construction lead-core rubber bearing Ⅰ type (LRB-Ⅰ) Building natural rubber bearing Ⅰ type (LNR-Ⅰ) |

Features: Superior performance, longer life, upgraded version |

| Specification: LRB/LNR-Ⅱ type (diameter: 200~ 1500mm) |

Zhejiang Earthquake Prevention Technology Co., Ltd. is a holding subsidiary established by Hangzhou Diping Zhenan Technology Co., Ltd. in September 2020. Zhejiang Zhenfang Technology Co., Ltd. has a registered capital of 26 million yuan, its own factory building covers an area of 10,800 square meters, and the standard factory building area is 6,000 square meters. With the great help of the Institute of Engineering Mechanics of China Earthquake Administration, the company has established a technical team led by domestic experts in seismic reduction and isolation technology, which has laid a solid foundation for long-term development in the future.

Zhejiang Earthquake Prevention Technology Co., Ltd is a member of China Disaster Prevention Association. Famous Building Vibration Isolation Rubber Bearings manufacturers and suppliers in China, we provide Building Vibration Isolation Rubber Bearings for better Seismic Isolation system.

In the realm of seismic engineering and infrastructure resilience, the concept of base isolation using low damping lead rubber bearings (LRBs) has gai...

Apr 26,2024

In the realm of earthquake engineering and structural resilience, low damping lead rubber bearings (LRBs) have emerged as critical components in mitig...

Apr 19,2024

In the realm of earthquake engineering, a groundbreaking technology is emerging to redefine seismic resilience: the low damping lead rubber bearing (L...

Apr 12,2024

In the realm of structural engineering and seismic resilience, lead rubber bearings (LRBs) stand out as crucial components that mitigate the impact of...

Apr 05,2024

It mainly includes the middle steel plate, the two outer steel plates and the friction material between the steel plates.

Simple and easy analysis and design of structural vibration reduction.

Even large earthquakes are not damaged, so there is no need to replace.

The hysteresis curve is basically rectangular.

Velocity correlation, displacement correlation is small.

No post-maintenance required.

Vertical bearing capacity, horizontal restoring force, damping (energy absorption) trinity.

Improved rubber formula, the equivalent damping ratio can reach more than 12%.

Low maintenance and management costs (no additional damping devices required).

HDR high damping rubber has low temperature dependence and is widely used in different climatic regions.

HDR high damping rubber has the same superior deformation performance as natural rubber.

The surface of the high damping bearing is covered with a rubber protective layer to protect the internal rubber from ozone and ultraviolet rays.

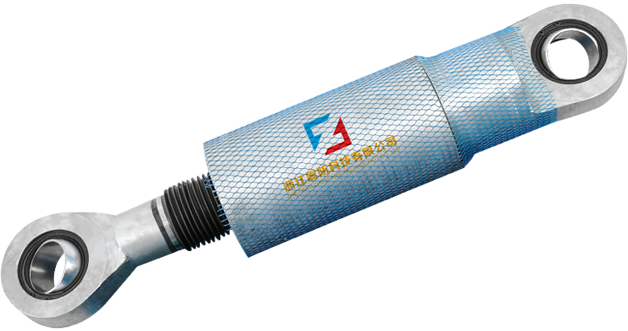

It is a kind of damper related to stiffness and speed.

It is used in high-rise buildings, bridges, seismic reconstruction of building structures and other fields.

The damper absorbs and dissipates the impact energy of the earthquake on the building structure to the maximum extent.

The medium has a small viscosity temperature coefficient, and good radiation resistance.

The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTE

Add: No. 359 Guangming West Road, Sanmen County, Taizhou City, Zhejiang Province, China

International Trade Manager: Madison

Tel/Whatsapp:+86-17857335842

Copyright © Zhejiang Earthquake Prevention Technology Co., Ltd. All Rights Reserved.