There are many classification methods for friction pendulum vibration isolation bearing structures, and they are often divided into three structural forms according to their performance:

1) The fixed bearing code is GD, which has strong vertical bearing performance, vertical steering performance, anti-drop beam performance and shock isolation performance.

2) The code name of the one-way movable bearing is DX. Compared with the fixed bearing, in addition to the vertical bearing performance, vertical rotation performance, anti-drop beam performance and shock isolation performance, this bearing also has a single direction. slip performance.

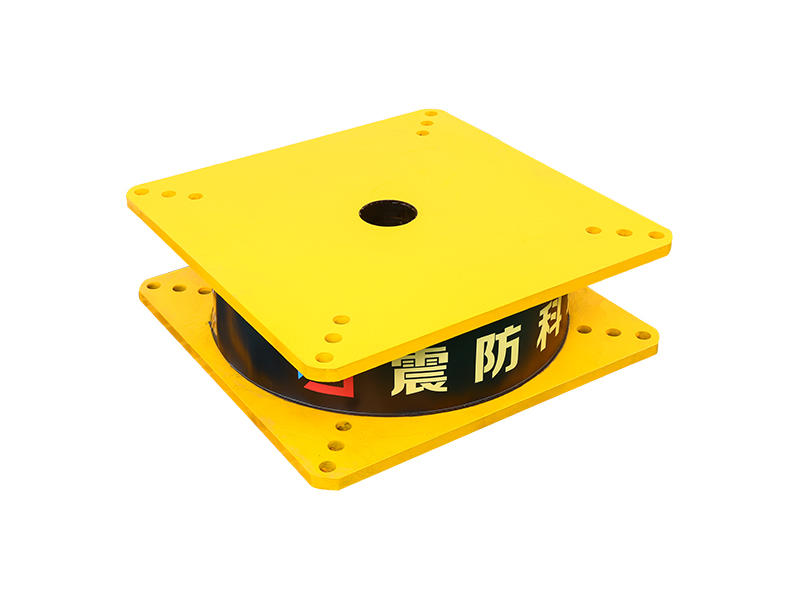

3) The code name of the multi-directional movable bearing is SX. From the name, it can be known that in addition to the vertical bearing performance, vertical rotation performance, anti-drop beam performance and shock isolation performance of the unidirectional movable bearing, the maximum The difference is that the support can slide in both directions.

The friction pendulum vibration isolation bearings are divided into fixed bearings, one-way movable bearings and two-way movable bearings according to their performance. difference.

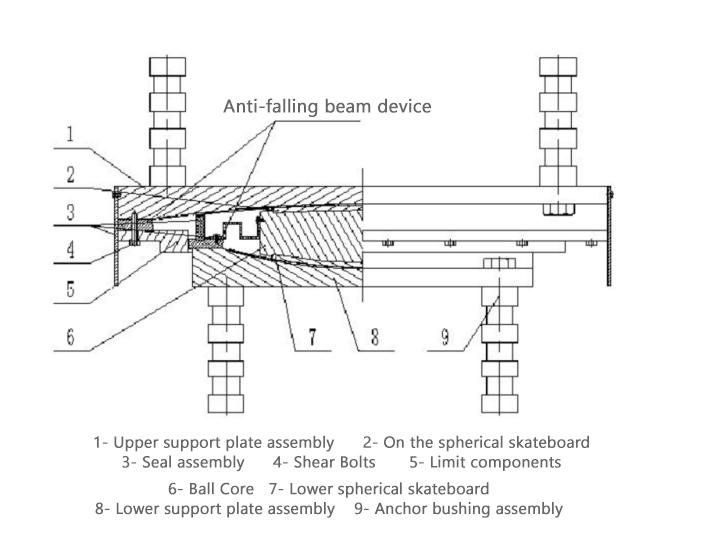

Its specific composition is as follows:

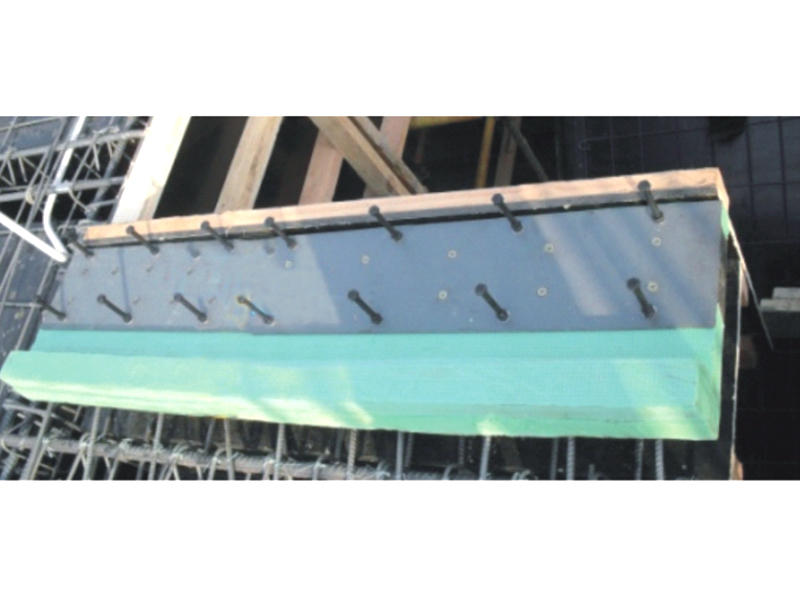

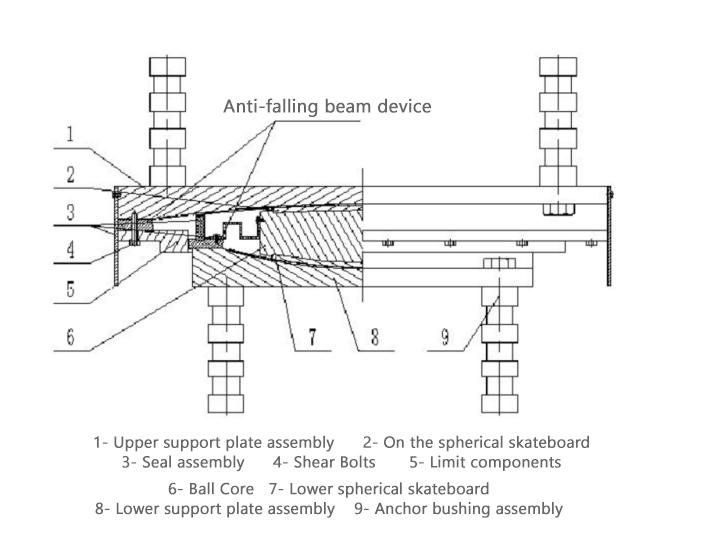

● GD consists of shock-absorbing top plate assembly, upper shock-absorbing slide plate, shock-absorbing ball pendulum, shear bolt, limit baffle, lower shock-absorbing slide plate, shock-absorbing bottom plate assembly, anti-fall beam structure, anchor bolt sleeve assembly and sealing assembly etc., wherein both the shock-absorbing top plate assembly and the bottom plate assembly contain stainless steel plates.

● DX consists of shock-absorbing top plate assembly, upper shock-absorbing slide plate, shock-absorbing ball pendulum, shear bolt, limit assembly, lower shock-absorbing slide plate, shock-absorbing bottom plate assembly, anti-fall beam structure, anchor bolt sleeve assembly and sealing assembly, etc. The structure, wherein the shock-absorbing top plate assembly contains stainless steel steel plate, and the shock-absorbing bottom plate assembly includes SF-1 composite plate in addition to stainless steel steel plate, and the limit assembly includes baffle plate and stainless steel plate.

● SX is composed of shock-absorbing top plate assembly, upper shock-absorbing sliding plate, shock-absorbing ball pendulum, lower shock-absorbing sliding plate, shock-absorbing bottom plate assembly, anti-drop beam structure, anchor bolt sleeve assembly and sealing assembly, among which, the shock-absorbing top plate assembly and baseplate assemblies contain stainless steel sheets.

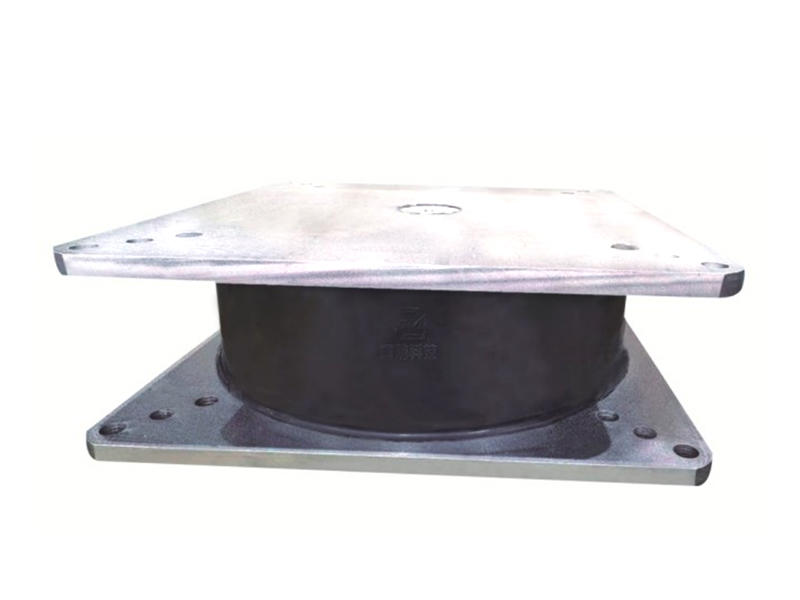

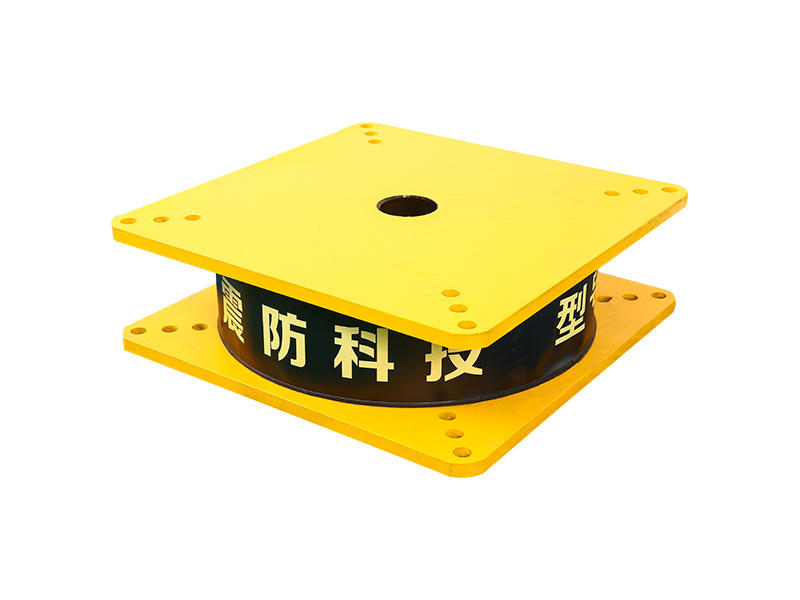

Schematic diagram of the fixed support structure:

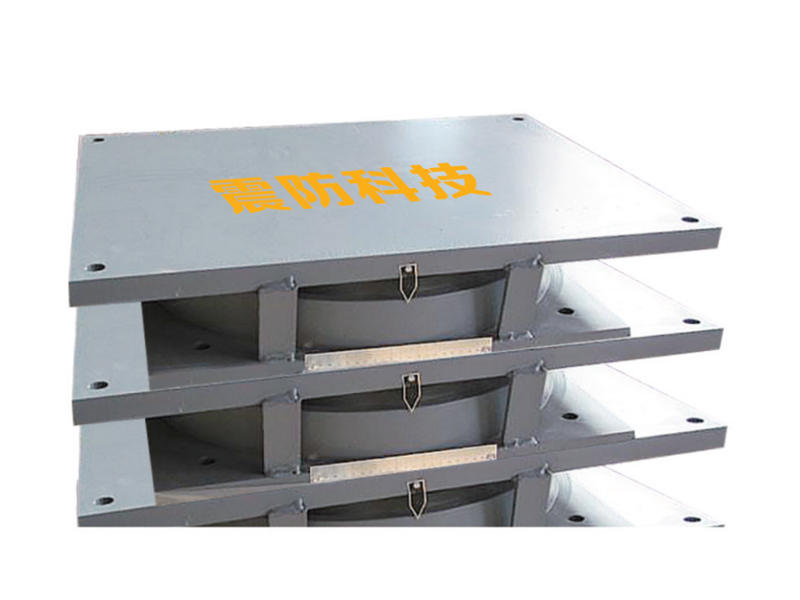

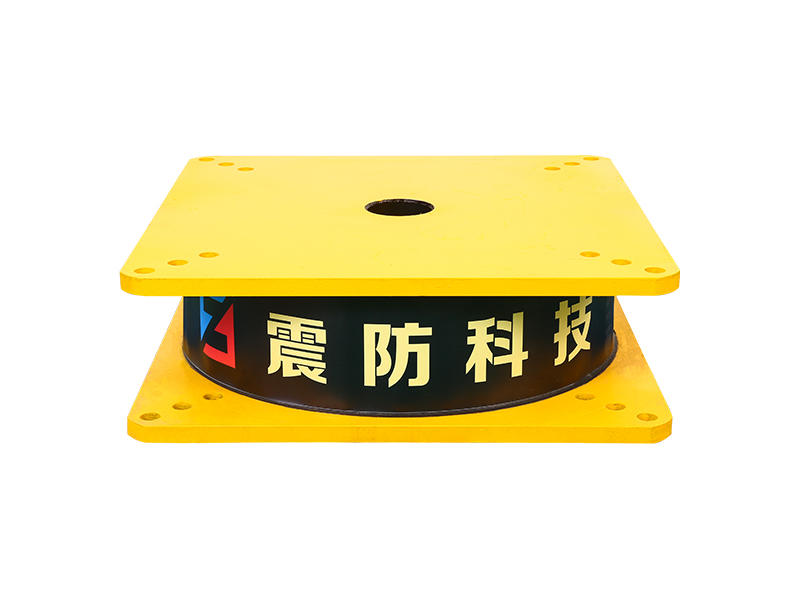

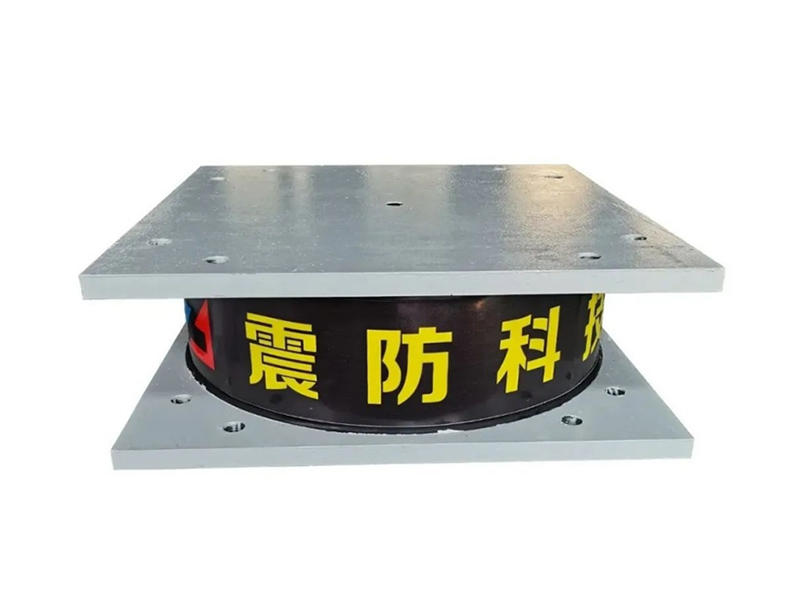

Friction pendulum shock-absorbing fixed bearing

English

English 日本語

日本語