In the ever-evolving world of structural engineering, a groundbreaking innovation is making waves – the

Metal Composite Damper. This advanced technology, blending metals and composites, is transforming the landscape of structural resilience and dynamic response. From seismic events to wind-induced vibrations, metal composite dampers are emerging as a versatile and efficient solution, revolutionizing the way engineers approach the challenges of structural design.

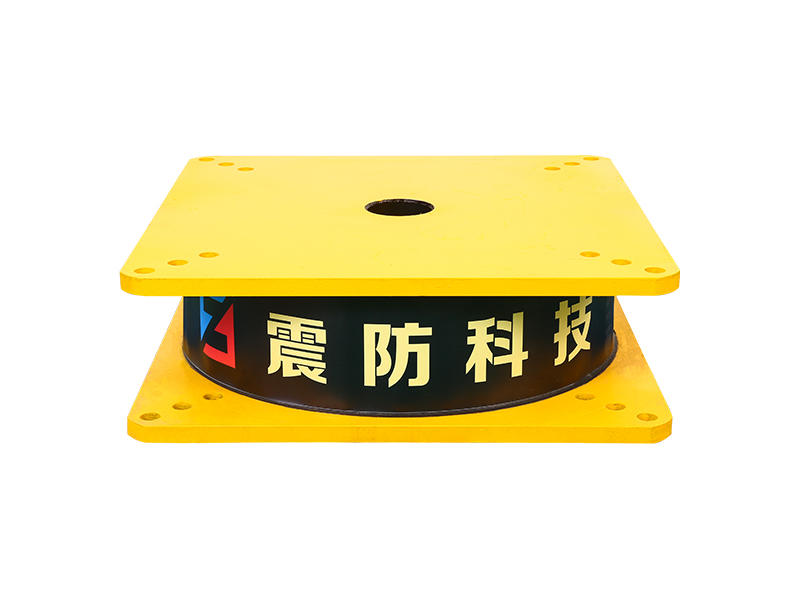

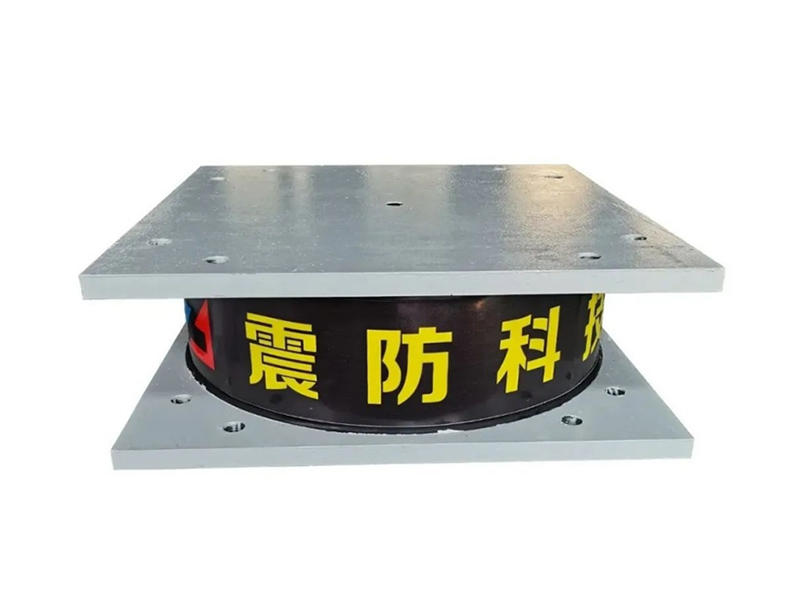

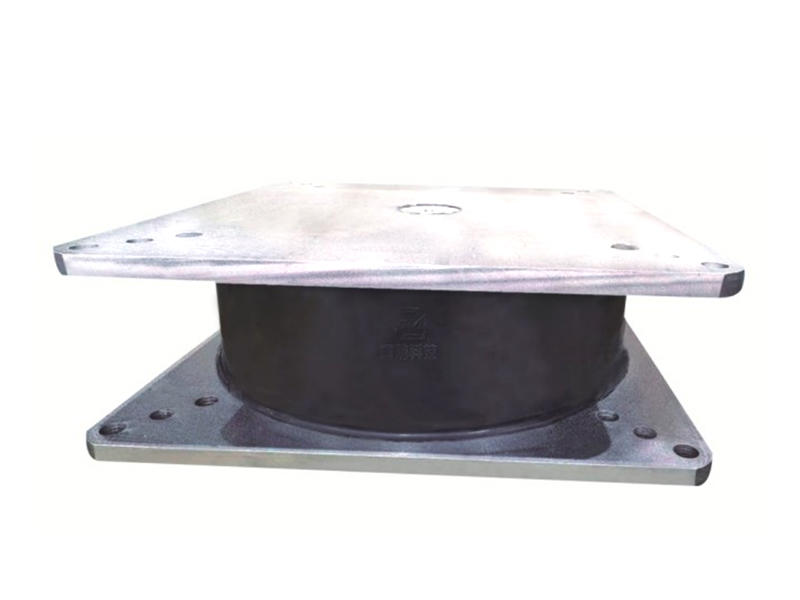

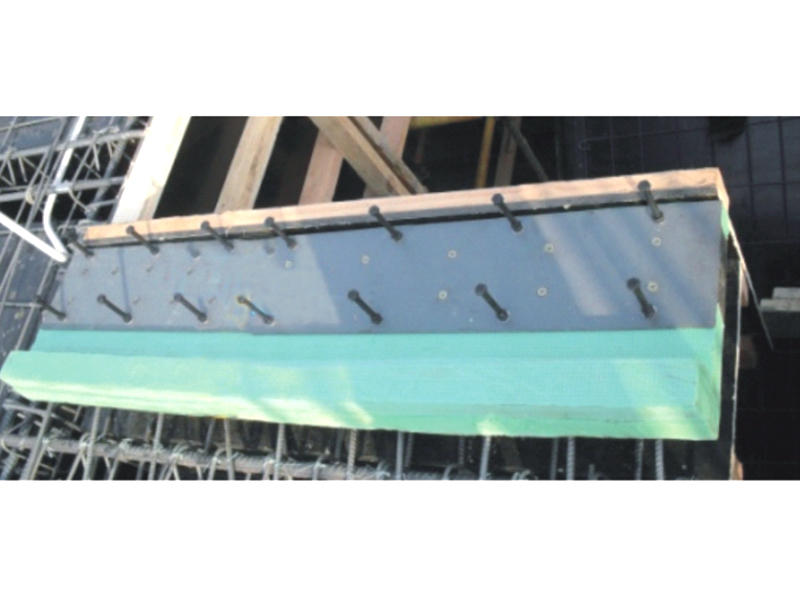

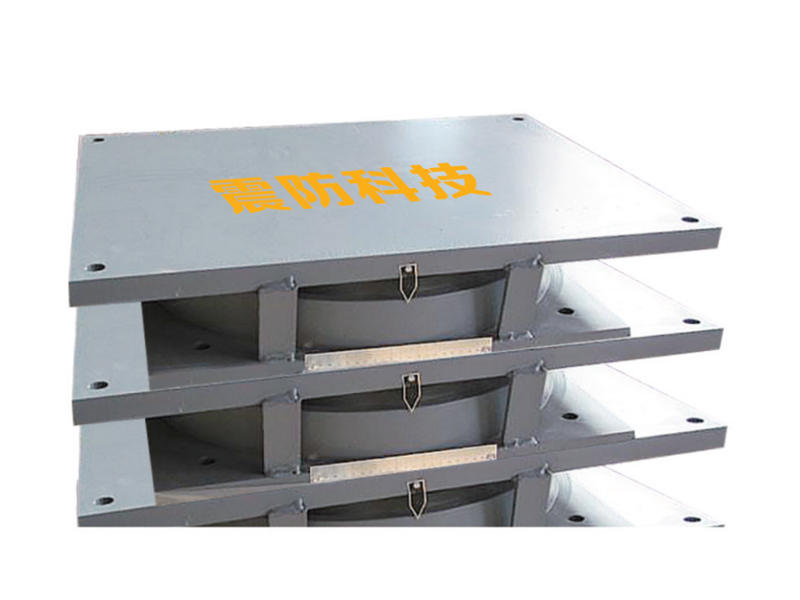

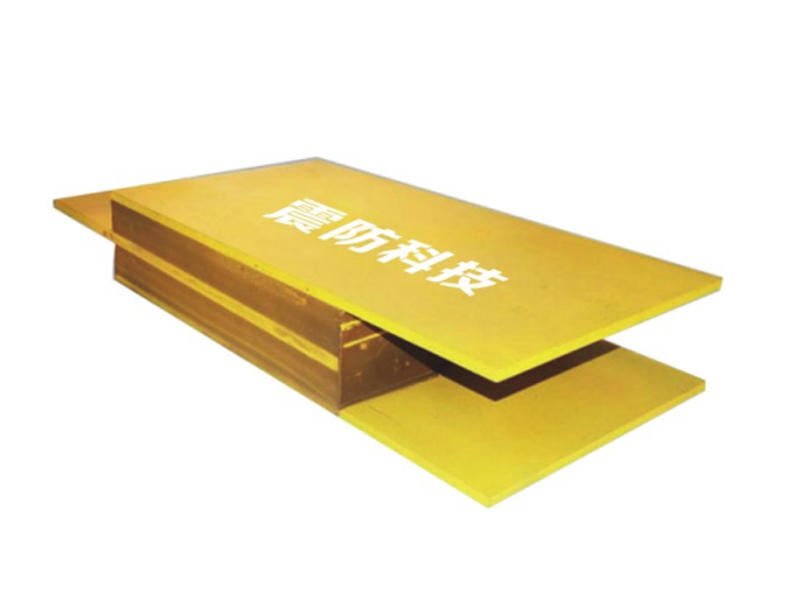

Metal composite dampers represent a fusion of traditional metals with modern composite materials. This combination leverages the strengths of both materials to create dampers that offer superior performance in absorbing and dissipating vibrational energy. The result is a more efficient and resilient solution that addresses the diverse needs of structures exposed to dynamic forces.

Seismic resilience is a primary application for metal composite dampers, where the demands on structural integrity are at their peak. In earthquake-prone regions, these dampers play a crucial role in mitigating the impact of seismic forces on buildings and infrastructure. The ability of metal composite dampers to absorb and dissipate energy helps reduce structural displacements and ensures the safety of occupants during seismic events.

One of the key advantages of metal composite dampers is their adaptability to a wide range of frequencies. Unlike traditional damping solutions, these dampers can be precisely tuned to target specific resonant frequencies of a structure. This level of customization allows engineers to address the unique characteristics of each building, enhancing their ability to control vibrations and optimize structural performance.

Wind-induced vibrations in tall structures pose another challenge that metal composite dampers are adept at addressing. As buildings reach new heights, the impact of wind forces becomes more pronounced. Metal composite dampers, strategically incorporated into the structure, act as tuned mass dampers, countering the effects of wind-induced oscillations and providing occupants with a more stable and comfortable experience.

The versatility of metal composite dampers extends beyond their role in seismic and wind engineering. These dampers find applications in mitigating vibrations induced by machinery and equipment within industrial settings. By effectively absorbing and dissipating vibrations, metal composite dampers contribute to the longevity of machinery, reduce noise levels, and create a safer and more productive work environment.

The composite component of metal composite dampers plays a significant role in their overall effectiveness. Composites, known for their lightweight and high strength-to-weight ratio, contribute to the efficiency and adaptability of these dampers. The incorporation of advanced composite materials enhances the overall performance of metal composite dampers, making them an attractive choice for modern engineering challenges.

As the demand for sustainable and resilient solutions grows, metal composite dampers align with the principles of eco-friendly engineering. Their ability to reduce the impact of dynamic forces translates to fewer repairs and maintenance, extending the lifespan of structures and reducing the environmental footprint associated with construction activities. The long-term sustainability of metal composite dampers positions them as a key player in the pursuit of green and resilient building practices.

The research and development in metal composite damper technology continue to evolve, with ongoing efforts to explore innovative materials and design concepts. The integration of smart technologies and sensors is on the horizon, promising a new era of adaptive dampers that can dynamically respond to changing environmental conditions. This evolution in damper technology holds the potential to further optimize the performance of structures in real-time.

In conclusion, metal composite dampers stand at the forefront of structural engineering innovation, offering a transformative solution to the challenges of dynamic forces. Their ability to seamlessly blend metals and composites, coupled with precise tuning capabilities, makes them a versatile and efficient choice for a wide range of applications. As the world looks towards resilient and sustainable building practices, metal composite dampers emerge as a beacon of progress in the quest for safer, more durable, and environmentally conscious structures.