The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTESeismic isolation bearing in high-rise buildings:

The development of building isolation technology in the world began in the 1960s. The United States and Japan have developed very mature isolation technology, not only establishing a comprehensive specification system, but also widely utilizing isolation technology in many high-rise and super-high-rise buildings. Many seismic isolation buildings with more than 30 floors have been built in Japan, such as the Umeda Super high-rise in Japan, which uses building isolation technology and has 1 underground floor, 50 above ground floors, and 2 tower floors. The structure's height is 1 68.5 m, and the tallest building is 177.4 m. The short side has an aspect ratio of 5.7, while the long side has an aspect ratio of 4.2.

For example, in Japan's Kobe City central district, Xu Tong four Ding Mu first city street three palace residential building, ground 54 floors, underground 1 floor, tower 2 floors, height 190 m, length 42.7 m, width 39 m, aspect ratio 4.51, there are 638 households, can park 305 units, a total construction area of 73479㎡, Leaded rubber bearings and elastic slide bearings are used in the base isolation form. It is currently the highest isolation building in the world, having been completed in 2013. Isolation technology research in China began in the 1980s, and it has been proven repeatedly in a wide range of practices.

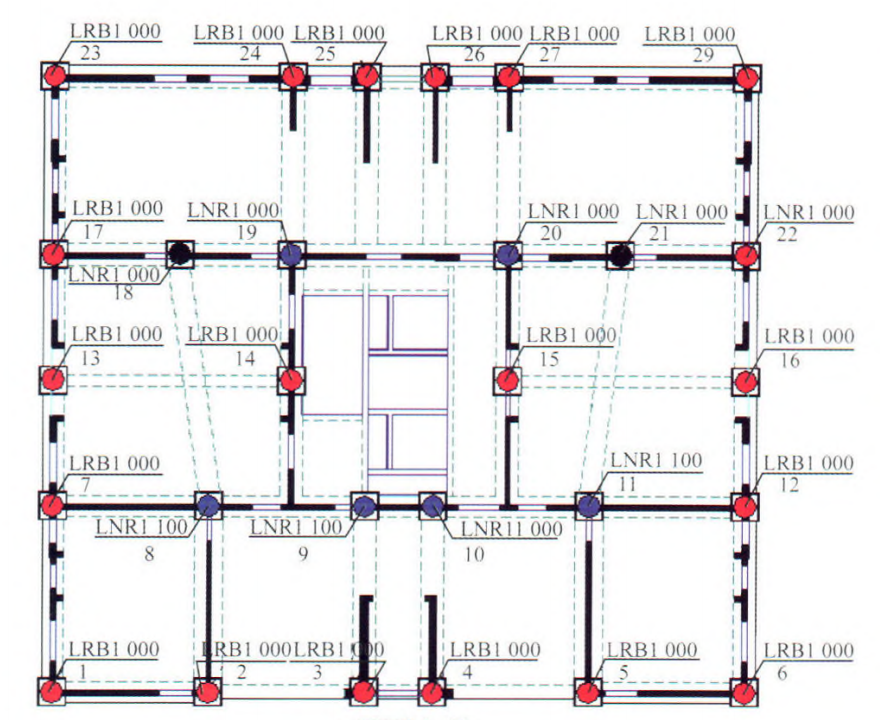

Yuxi Public Rental Housing has a maximum height-to-width ratio of 3.96 and a height of 94.7 m. The period of the non-isolated structure is 1.536 S because the upper structure is a shear wall structure, and a long shear wall design scheme is used to increase the stiffness of the upper structure. with the aid of seismic isolation technology. The isolation floor is designed with a rubber bearing that has a relatively low shear modulus, and the isolated structure's period is 4.4 1 2 S. The isolation floor was intended to serve as the transfer floor. The distribution of isolated pillars is even, and the rubber bearings' compressive stress is more uniform, both of which increase their effectiveness.

Additionally, it enhances the regularity of the basement's structure and its ability to serve its intended purpose. To increase the dependability of the isolation design, isolation bearings with diameters greater than 1000 mm have been used. The horizontal earthquake action is reduced by 50% as a result of seismic isolation analysis using three-direction ground motion input, and the design indices satisfy code requirements. The economy of the upper structure can be maximized by using the interpolation method to calculate the minimum seismic shear coefficient.

Yuxi Public Rental Housing

Plane layout of the seismic isolation rubber bearings

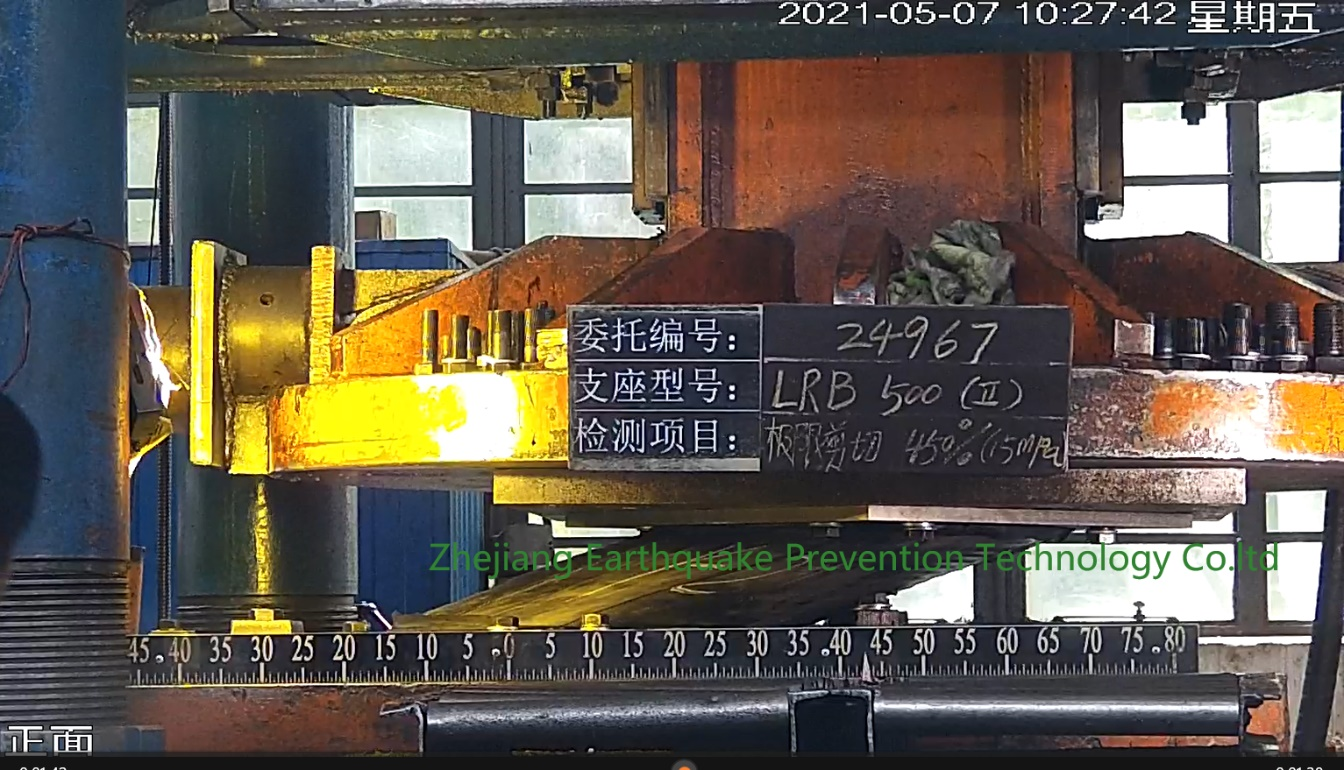

In this project, the isolation bearing is rubber bearing with a diameter of more than 1000mm. Under the reference compressive stress of 12MPa, the shear strain of the bearing can reach 400%.

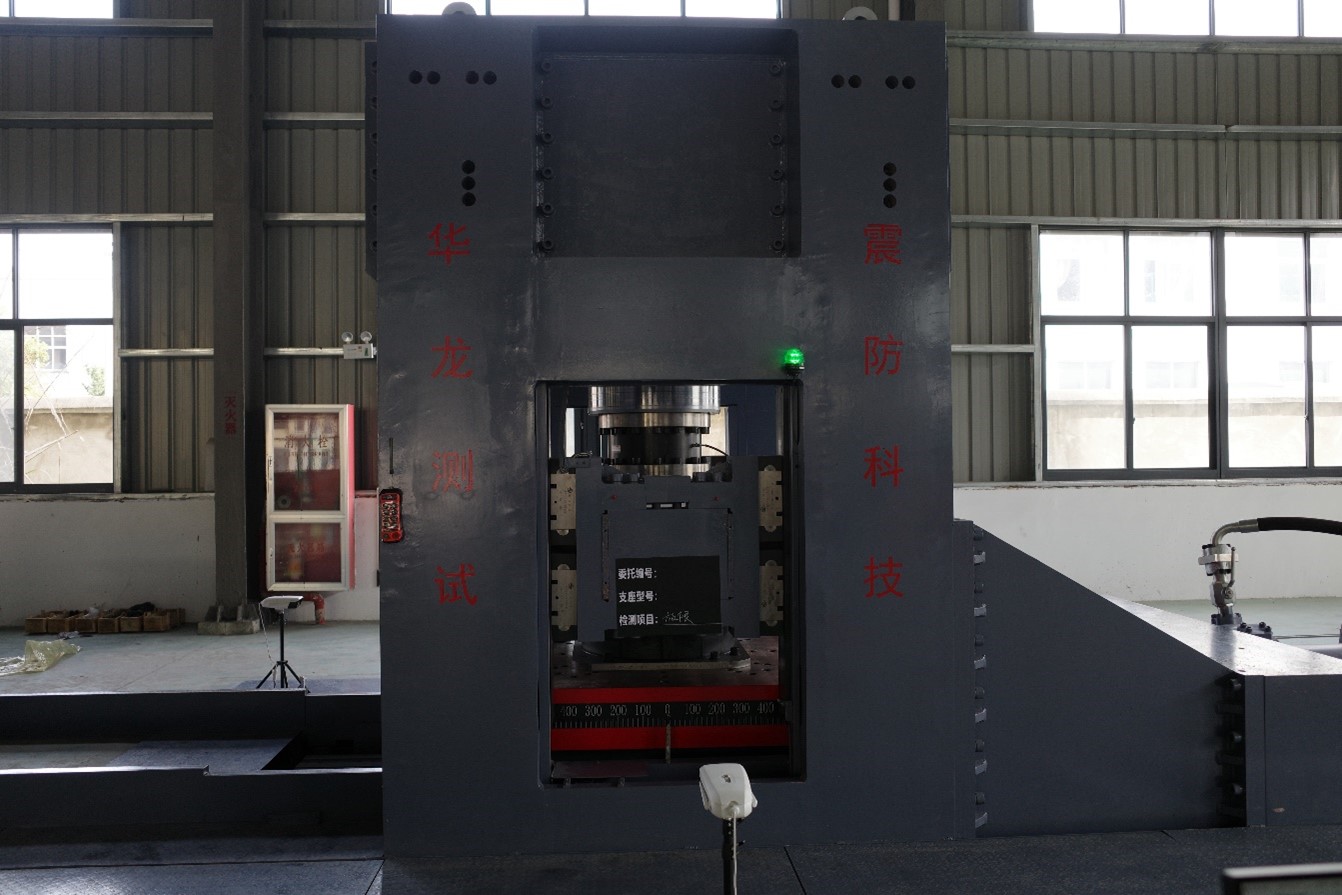

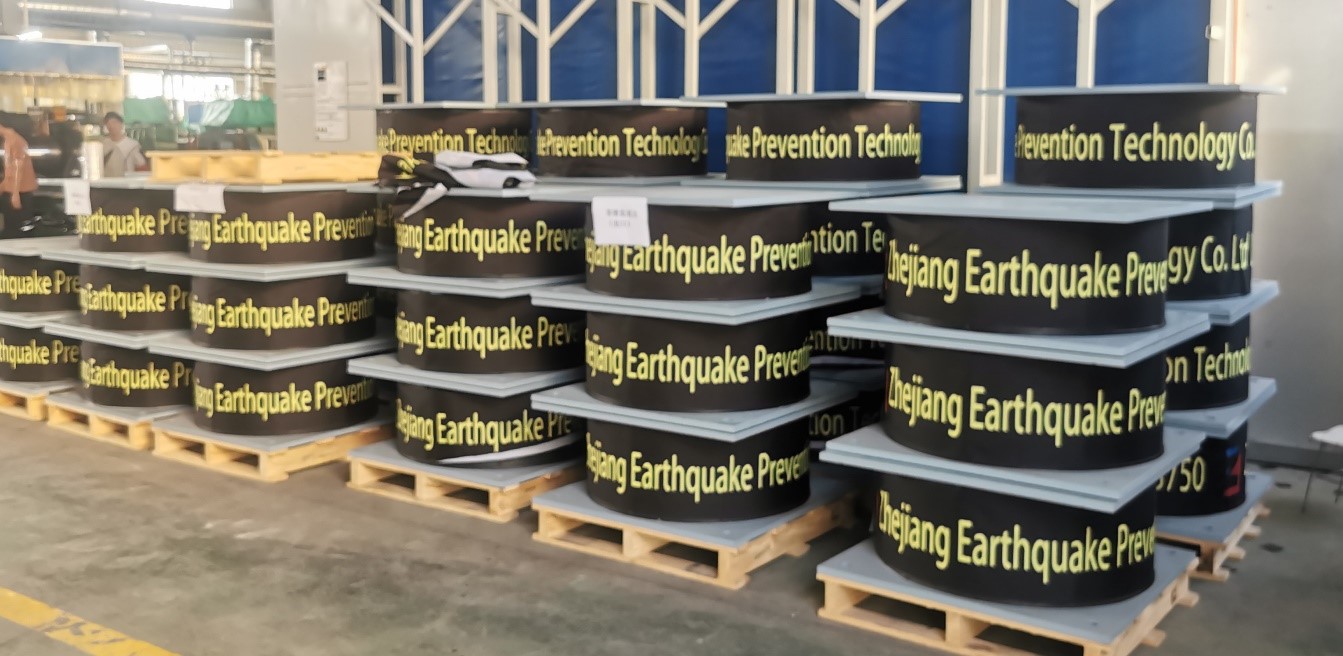

Zhejiang Earthquake Prevention Technology Co., Ltd. factory equipped with a 20000KN compressive shear testing machine, a 5000KN, 10000 universal hydraulic testing machine, can meet the company's isolation bearing factory inspection. The isolation bearing produced by our company has been measured. The shear strain of the bearing can reach 450%. All parties are welcome to consult and purchase.

20000KN compressive shear testing machine

Third party inspection record of LRB500

Shipping Arz

Contact us:

Madison

Email: [email protected]

WhatsApp:+86 17857335842