A friction pendulum isolation bearing can help isolate a bearing system during seismic activity. Its basic design follows Coulomb's friction theory, which states that the friction coefficient is constant regardless of the bearing pressure. However, the coefficient of friction can also change depending on the sliding velocity and temperature. Various velocity-dependent and constant friction coefficients have been studied in order to better understand the response of this type of bearing system.

Concave plate geometry

The hysteretic behavior of a friction pendulum isolation bearing is dependent on the concave plate geometry. This geometry results in a base-isolated structure, where the input energy of an earthquake is dissipated into the base.

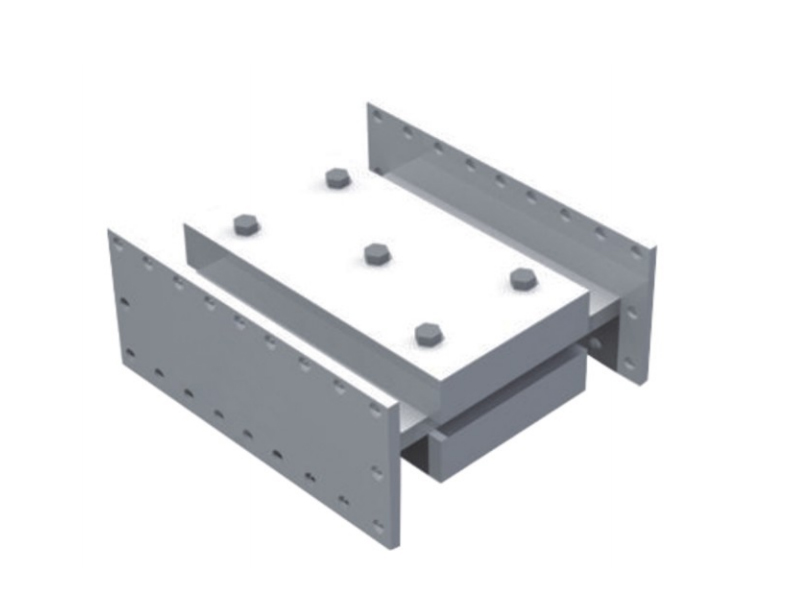

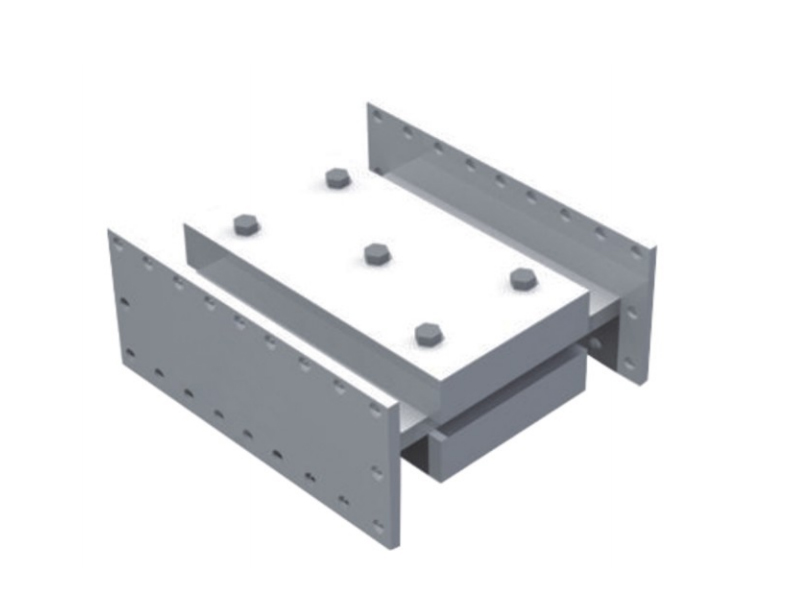

The geometry of a friction pendulum isolation bearing consists of a pair of concave steel plates with a slider made of a non-metallic sliding material. The total bearing motion is the motion of the slider relative to plate 0. The plate size of a double FP is selected to be smaller than the size of a triple FP.

The concave plate geometry is important because it improves the isolation performance of the triple FP. The triple FP has two concave plates with concave surfaces of equal radii. The double FP has concave plates 0 and 4 that are the same as those of the triple FP. In addition, the equivalent friction and stiffness coefficients of the double FP depend on the amplitude of the bearing.

Shock-absorbing ball pendulum

Shock-absorbing ball pendulum isolation is a type of bearing used in the pendulum movement. Its spherical shape, concave surface, and energy-dissipating design reduce internal forces and displacements. The ball is fixed on the swing seat by a sliding friction pair and arranged on a convex spherical base. The energy-dissipating base is made of a chromium plate.

Shock-absorbing ball pendulum isolation isolators have an inner slider that slides along two concave surfaces. This inner slider minimizes displacements in earthquakes and minimizes structural base shears. The inner slider is 60% the size of the Single Pendulum isolator.

Shock-absorbing bottom plate

A friction pendulum isolation bearing dissipates seismic energy and allows the supported structure to move horizontally. Because of its high stiffness and low friction, the bearing is a good choice for new construction and for restoring stiffness to existing structures. It is widely used in the construction industry, including bridges and tunnels.

The friction-based isolator can be either double or triple pendulum. The latter is more complex than a single pendulum bearing because of multiple friction surfaces. The model was calibrated against experimental data in order to make sure that the proposed parameters matched the actual performance of the bearing.

The NRB had a higher compressive stiffness and was found to be a superior choice. The LRB, on the other hand, was found to have a lower compression capacity than the NRB and had a lower shock absorption capacity than the EQS.