The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTEEarthquakes are among the devastating natural disasters, capable of causing massive structural damage and endangering lives. To counter this, engineers have developed various seismic protection technologies, with one of the effective being the Linear Base Seismic Isolation Rubber Bearing. This advanced device is designed to minimize the transmission of ground motion to structures during seismic events, thereby significantly reducing potential damage.

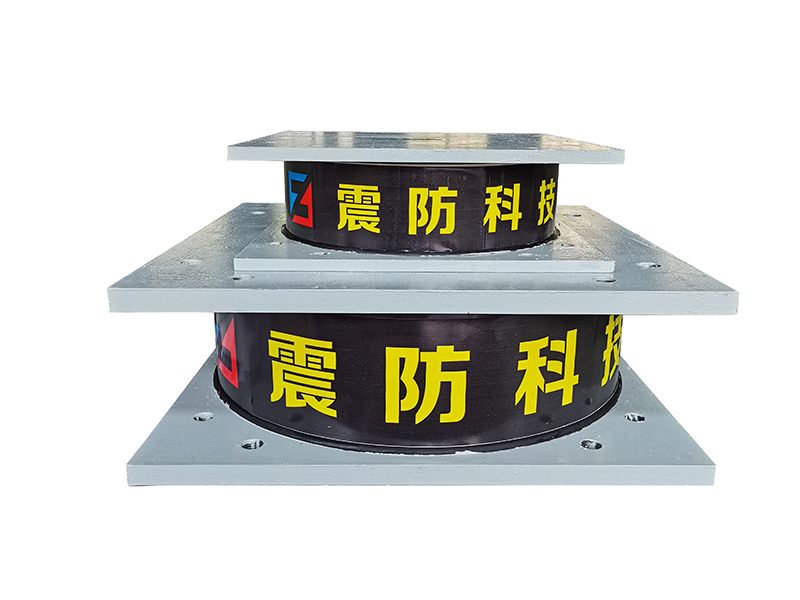

The Linear Base Seismic Isolation Rubber Bearing is a specialized component installed between a building’s foundation and its superstructure. Its primary function is to decouple the structure from ground motion during an earthquake. Unlike fixed-base structures that move with the ground, structures using a Linear Base Seismic Isolation Rubber Bearing can "float" independently, absorbing and reducing seismic energy. This isolation mechanism greatly improves a building’s ability to remain intact and operational after an earthquake.

One of the defining characteristics of the Linear Base Seismic Isolation Rubber Bearing is its combination of flexibility and load-bearing capacity. It is composed of alternating layers of rubber and steel, which provide horizontal flexibility while maintaining vertical stiffness. The linear behavior of this bearing ensures predictable and stable performance under a range of seismic loads. This predictability is crucial in seismic engineering, where reliability and precision determine the effectiveness of protective systems.

Moreover, the Linear Base Seismic Isolation Rubber Bearing significantly enhances the seismic resilience of both new and retrofitted buildings. In new construction, these bearings can be incorporated at the design stage, allowing architects and engineers to optimize the structure's layout with seismic performance in mind. For existing buildings, retrofitting with Linear Base Seismic Isolation Rubber Bearings provides a cost-effective means of upgrading seismic safety without altering the original architectural integrity.

The performance of the Linear Base Seismic Isolation Rubber Bearing during real earthquakes has been well documented. Structures equipped with this technology have consistently demonstrated lower levels of acceleration and deformation compared to those without isolation systems. Hospitals, bridges, government buildings, and cultural landmarks are some of the common beneficiaries of this innovation. The enhanced protection provided by Linear Base Seismic Isolation Rubber Bearings helps safeguard not only physical infrastructure but also human life and critical operations during seismic crises.

Another important aspect of the Linear Base Seismic Isolation Rubber Bearing is its durability. These bearings are designed to function effectively over several decades, even in harsh environmental conditions. The rubber layers are treated to resist aging and degradation, while the steel plates offer long-term structural integrity. This durability ensures that buildings remain protected throughout their lifecycle with little maintenance.

From a cost-benefit perspective, the use of Linear Base Seismic Isolation Rubber Bearing can result in substantial long-term savings. Although the initial investment may be higher compared to traditional construction methods, the reduced repair costs and downtime following an earthquake make it a financially sound choice. Insurance goods may also be lower for buildings equipped with advanced seismic isolation, further enhancing economic feasibility.

In the context of sustainable construction, the Linear Base Seismic Isolation Rubber Bearing aligns well with green building principles. By protecting structures from damage, it reduces the need for reconstruction and material waste after earthquakes. This supports a more sustainable approach to urban development, especially in earthquake-prone regions.

The widespread adoption of the Linear Base Seismic Isolation Rubber Bearing also promotes public confidence in infrastructure safety. Knowing that essential facilities are equipped with good seismic protection can reassure communities and policymakers alike. In countries such as Japan, the United States, and Chile, where seismic activity is frequent, this technology is becoming a standard practice in modern engineering.