The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

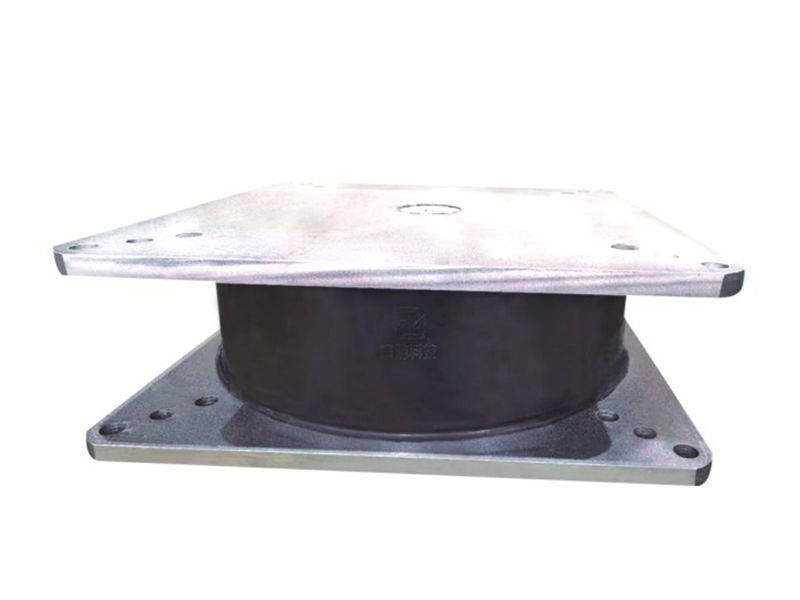

GET A QUOTEThe construction industry continues to adopt advanced seismic protection systems with the building isolation rubber bearing emerging as a significant component in structural engineering. This specialized device serves a crucial role in protecting structures from various dynamic forces, including seismic events and environmental vibrations. The fundamental design of a building isolation rubber bearing typically incorporates layered rubber and steel plates that work together to provide both vertical support and horizontal flexibility. Engineering professionals increasingly recognize the value of incorporating a building isolation rubber bearing system to enhance structural resilience and occupant safety.

The operational principle of the building isolation rubber bearing centers on its ability to decouple a structure from ground motions during dynamic events. When properly installed, the building isolation rubber bearing allows for controlled horizontal movement while maintaining vertical load-bearing capacity. The unique properties of the building isolation rubber bearing enable it to absorb and dissipate energy that would otherwise transfer to the structure above. This functionality of the building isolation rubber bearing helps reduce structural damage and improves performance during seismic activity. The reliability of the building isolation rubber bearing has been demonstrated through extensive research and practical application.

Manufacturing standards for the building isolation rubber bearing require precise engineering and quality control measures. The production process for a building isolation rubber bearing involves carefully alternating layers of rubber and steel, which are bonded together under specific conditions. The rubber compound used in a building isolation rubber bearing must meet strict specifications for durability, aging resistance, and mechanical properties. Quality assurance testing for each building isolation rubber bearing includes evaluations of compression capacity, shear performance, and environmental resistance. These manufacturing protocols ensure that every building isolation rubber bearing performs as intended in real-world conditions.

Installation procedures for the building isolation rubber bearing demand careful planning and execution by experienced professionals. The placement of each building isolation rubber bearing requires precise leveling and alignment to ensure uniform load distribution. Construction teams must follow specific guidelines when integrating the building isolation rubber bearing into the foundation system of a structure. The implementation of a building isolation rubber bearing system typically occurs during the early stages of construction, though retrofit applications are also possible. Proper installation is essential for the building isolation rubber bearing to function as designed throughout the structure's lifespan.

Application of the building isolation rubber bearing technology spans various structure types and geographical regions. Critical facilities such as hospitals and emergency response centers frequently incorporate the building isolation rubber bearing to maintain functionality after seismic events. Commercial and residential buildings in seismically active areas increasingly utilize the building isolation rubber bearing to enhance safety and reduce potential damage. Bridge structures also employ variations of the building isolation rubber bearing to accommodate thermal expansion and seismic movements. The versatility of the building isolation rubber bearing makes it suitable for both new construction and structural retrofit projects.

The future development of building isolation rubber bearing technology appears likely to focus on adaptive systems and improved cost-effectiveness. Next-generation designs of the building isolation rubber bearing may incorporate smart materials that can adjust their properties in response to changing conditions. The building isolation rubber bearing remains an important tool for structural engineers seeking to create safer built environments in regions prone to seismic activity and other dynamic loads.