The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

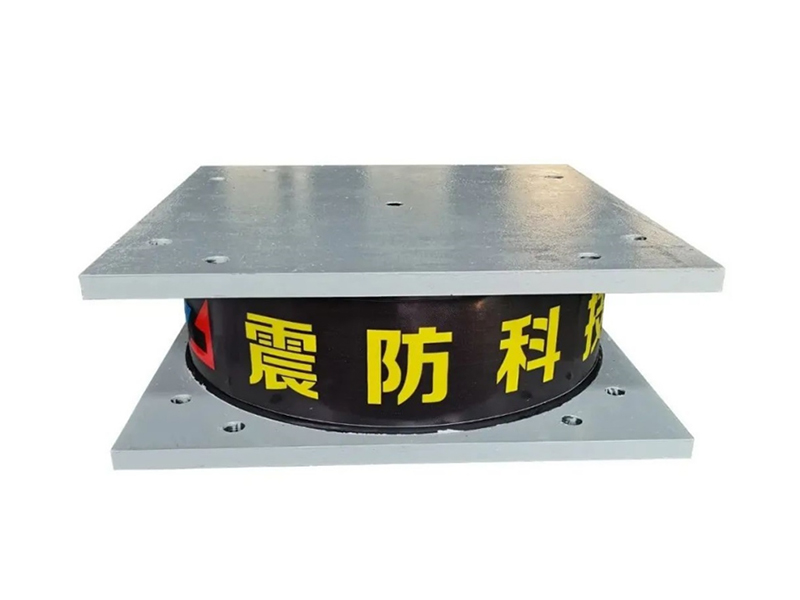

GET A QUOTEThe field of linear motion systems continues to benefit from the unique properties offered by the linear rubber bearing, a specialized component that provides distinct advantages in certain operating environments. This type of bearing incorporates elastic elements that differentiate it from traditional rigid linear guidance systems. The fundamental design of a linear rubber bearing typically involves a metal core surrounded by a precisely engineered rubber composition that provides both support and flexibility. Manufacturers have developed various configurations of the linear rubber bearing to address specific application requirements across different industries.

The operational principle of the linear rubber bearing centers on its ability to accommodate minor misalignments and absorb vibrations during linear movement. Unlike conventional linear bearings that require precise alignment, the linear rubber bearing can compensate for small installation inaccuracies without compromising performance. The elastic characteristics of the linear rubber bearing also contribute to reduced noise levels during operation, making it suitable for applications where quiet performance is valued. The damping properties inherent in the linear rubber bearing help protect sensitive equipment from shock loads and vibration transmission.

Manufacturing processes for the linear rubber bearing involve specialized techniques to ensure consistent quality and performance. The production of a reliable linear rubber bearing requires careful formulation of the rubber compound to achieve the desired hardness, durability, and resistance to environmental factors. The bonding between the rubber element and metal components in a linear rubber bearing receives particular attention during manufacturing to ensure long-term integrity. Quality control measures for the linear rubber bearing typically include testing for load capacity, elasticity, and dimensional accuracy. These manufacturing standards help maintain the performance characteristics that users expect from a quality linear rubber bearing.

Application areas for the linear rubber bearing span multiple industries where its specific advantages provide operational benefits. The automotive industry utilizes the linear rubber bearing in various assemblies where vibration damping and misalignment compensation are beneficial. Industrial automation systems incorporate the linear rubber bearing in applications requiring smooth linear motion with reduced maintenance requirements. The packaging industry employs the linear rubber bearing in machinery where shock absorption helps protect delicate products during handling. Medical equipment manufacturers value the linear rubber bearing for its quiet operation and contamination reduction capabilities in sensitive environments.

Installation considerations for the linear rubber bearing differ somewhat from those for conventional linear bearings. The mounting procedure for a linear rubber bearing typically allows for greater tolerance in alignment while still ensuring proper function. The maintenance requirements for a linear rubber bearing generally involve periodic inspection of the rubber elements for signs of wear or deterioration. Lubrication needs for the linear rubber bearing may differ from metal-based linear bearings, with some designs operating effectively with small or no lubrication. These practical aspects contribute to the overall value proposition of the linear rubber bearing in appropriate applications.

Future prospects for the linear rubber bearing appear connected to broader trends in machinery design and operational requirements. The movement toward more environmentally sustainable manufacturing may influence material selection for future linear rubber bearing products. The continued evolution of the linear rubber bearing will probably focus on enhancing its performance characteristics while expanding its suitability for emerging applications across various industrial sectors.