The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTEA critical technology in modern seismic and vibration engineering, the building isolation rubber bearing, is witnessing increased adoption in construction projects within active seismic zones and areas sensitive to environmental vibrations. This specialized component is installed at the base of a structure, between the foundation and the superstructure, with the primary function of decoupling the building from ground motions. The strategic use of the building isolation rubber bearing allows a structure to move independently to a certain degree, significantly reducing the transfer of seismic energy or ground-borne vibrations into the building above.

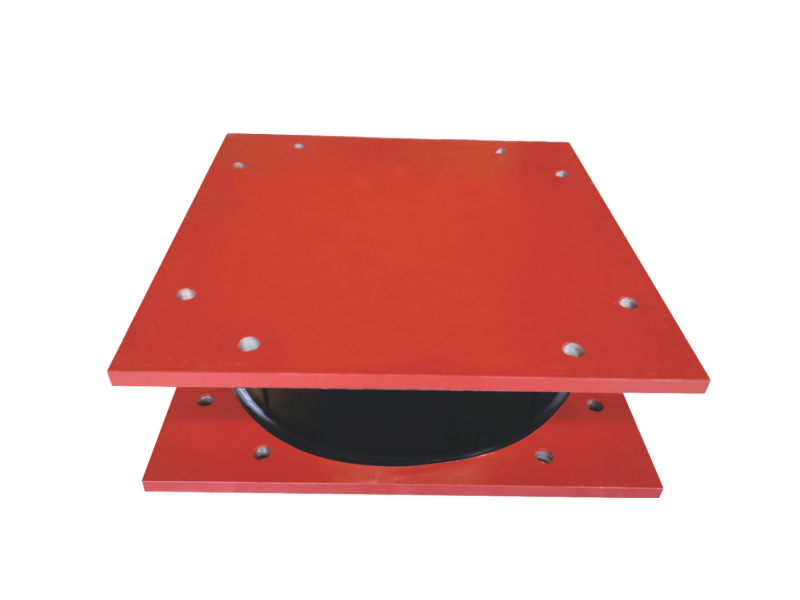

The core of the building isolation rubber bearing is a multi-layered composite of steel plates and high-damping rubber. This laminated design provides the building isolation rubber bearing with its two essential mechanical properties: high vertical stiffness to support the weight of the structure, and low horizontal stiffness to permit flexible lateral movement. When ground shaking occurs, the building isolation rubber bearing deforms horizontally. The rubber layers shear, absorbing and dissipating a substantial portion of the seismic energy as heat, while the embedded steel plates ensure the bearing maintains its load-bearing capacity and stability. This mechanism fundamentally alters a building's response, shifting its fundamental period and reducing floor accelerations.

The primary application driving the specification of the building isolation rubber bearing is seismic protection. For critical infrastructure such as hospitals, emergency response centers, data hubs, and museums, the integration of a building isolation rubber bearing system is considered a proactive investment in continuous functionality and life safety during and after an earthquake. Bridges also utilize large-scale versions of the building isolation rubber bearing to accommodate thermal expansion and seismic movements at supports. Beyond seismic regions, the building isolation rubber bearing is employed to protect sensitive buildings, like research laboratories and high-precision manufacturing facilities, from the disruptive effects of nearby traffic or rail vibrations.

The design and implementation of a building isolation rubber bearing system require sophisticated engineering analysis. Each project involves calculating the specific dynamic properties needed and customizing the bearings accordingly. Factors such as the building's weight, its desired period shift, and the anticipated seismic or vibration spectra influence the final specifications of every building isolation rubber bearing in the system.

Ongoing research and development in the field of the building isolation rubber bearing focus on enhancing performance and longevity. Innovations include the use of advanced rubber compounds with higher damping properties, pilot to a more efficient building isolation rubber bearing that dissipates more energy. Furthermore, the long-term durability of the building isolation rubber bearing, including its resistance to environmental aging and creep under constant load, remains a key area of study and quality assurance in manufacturing.

The use of the building isolation rubber bearing is expected to expand as building codes in seismic regions evolve and the value of resilient infrastructure becomes more widely recognized. Trends may include more cost-effective designs for mid-rise residential and commercial buildings, broadening the technology's application beyond high-value or critical structures. This approach, centered on the strategic deployment of the building isolation rubber bearing, continues to redefine standards for safety and functionality in construction, offering a demonstrable means to protect both the physical structure and the people and assets within it from the damaging effects of earthquakes and disruptive vibrations.