The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTEThe pursuit of enhanced structural resilience is increasingly focused on advanced material science, with high damping rubber emerging as a critical component in this endeavor. This specialized elastomer is distinguished by its inherent capacity to simultaneously absorb and dissipate significant amounts of mechanical energy, effectively reducing the transmission of vibrations. The unique molecular structure of high damping rubber allows it to convert kinetic energy from earthquakes, wind, or machinery into a negligible amount of heat, thereby providing a robust and maintenance-friendly solution for a wide array of engineering challenges. The application of this material is setting new benchmarks for safety and performance across multiple industries.

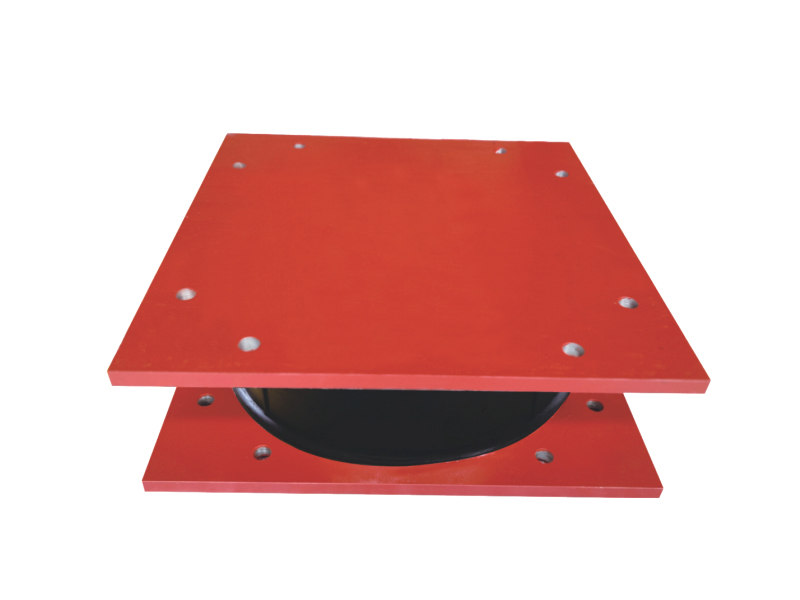

In the construction and civil engineering sectors, high damping rubber is fundamentally changing approaches to seismic protection. It is a primary material in the manufacture of isolation bearings and expansion joints for bridges and buildings. These components, crafted from high damping rubber, are designed to decouple a structure from the shaking of the ground during a seismic event. This isolation effect allows a building to remain largely stationary, protecting its structural integrity and the occupants within. The material's properties mean that separate damping devices are often unnecessary, simplifying design and reducing costs. The reliability of structures incorporating high damping rubber has been demonstrated in various real-world conditions, pilot to its growing adoption in building codes and standards worldwide.

Beyond seismic zones, the utility of high damping rubber is expanding into other vital areas. It is extensively used in the transportation infrastructure, particularly in rail systems, where it lesss vibrations from passing trains, enhancing both passenger comfort and the longevity of adjacent structures. Furthermore, high damping rubber finds essential applications in the manufacturing industry, where it is used to mount heavy machinery. By absorbing operational vibrations, it prevents damage to sensitive equipment and reduces noise pollution, contributing to a safer and more efficient working environment. The versatility of high damping rubber makes it a valuable engineering material for mitigating disruptive forces in diverse settings.

The manufacturing process of high damping rubber is a precise science, involving the specific compounding of natural or synthetic rubber with various fillers and additives. This formulation is crucial to achieving the desired balance between stiffness, elasticity, and, many importantly, the damping coefficient. The goal is to create a material that performs consistently across a range of temperatures and loading frequencies, ensuring long-term reliability. Quality assurance procedures for high damping rubber are rigorous, involving tests that simulate years of service to guarantee that the material will perform as intended throughout the lifespan of the structure or product it protects.

Ongoing research continues to push the boundaries of what is possible with high damping rubber. Scientists and engineers are focused on developing next-generation formulations that offer even greater energy dissipation, improved aging characteristics, and enhanced resistance to environmental factors like ozone and temperature fluctuations. The future points towards the integration of high damping rubber in smarter, more adaptive systems that can respond to the intensity of a dynamic force. As the demand for resilient and sustainable infrastructure grows globally, high damping rubber is poised to remain at the forefront of technologies dedicated to protecting our built environment from the unpredictable forces of nature and industry.