The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTEThe field of seismic and vibration protection is experiencing a significant shift, driven by advancements in the design and application of the natural rubber isolation bearing. This specialized component, a cornerstone of base isolation systems, is increasingly recognized for its ability to safeguard structures from the destructive forces of earthquakes and ambient vibrations. At the heart of this technology lies a sophisticated use of natural rubber, which provides a unique combination of flexibility, durability, and energy absorption. The ongoing evolution of the natural rubber isolation bearing is setting new benchmarks for safety and resilience in construction and infrastructure projects worldwide.

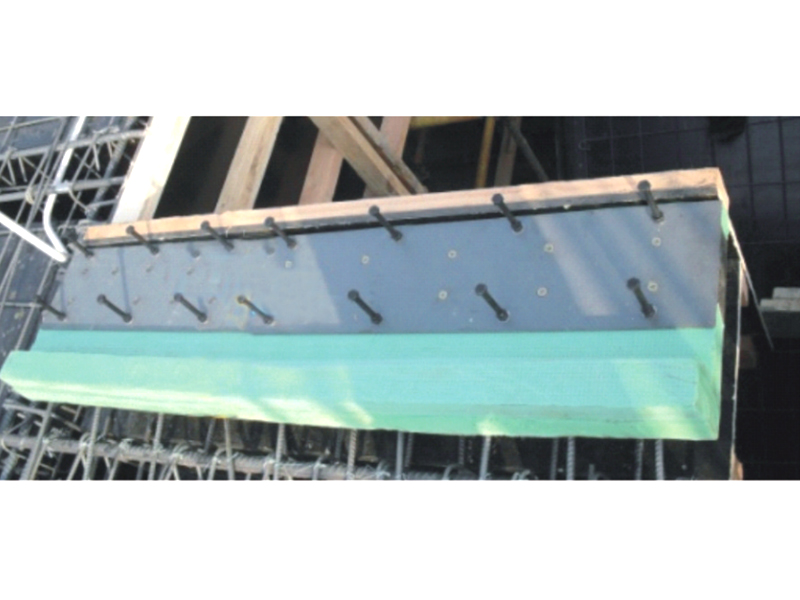

The fundamental principle behind the natural rubber isolation bearing is its capacity to decouple a building or bridge from the ground motion. During a seismic event, the bearing deforms horizontally, allowing the structure above to remain relatively stable while the ground beneath it moves. This mechanism significantly reduces the transfer of destructive energy to the building. The key to this performance is the layered composition of the natural rubber isolation bearing, which typically consists of multiple sheets of natural rubber bonded to steel plates. This configuration provides high vertical stiffness to support the structure's weight while maintaining low horizontal stiffness, permitting the necessary movement. The inherent properties of natural rubber, including its elasticity and damping characteristics, are crucial for this function.

Manufacturing a high-performance natural rubber isolation bearing is a precise engineering endeavor. The process involves carefully selecting and compounding the natural rubber to achieve specific mechanical properties, such as shear modulus and damping ratio. The vulcanization process that bonds the rubber to the steel plates is critical, ensuring a durable and inseparable interface that can withstand repeated cycles of deformation. Quality control is paramount, with each natural rubber isolation bearing undergoing rigorous testing to verify its performance under simulated load conditions. This meticulous attention to detail ensures that every unit delivered to a construction site meets the exacting standards required for life-safety applications.

The applications for this technology are expanding beyond traditional seismic zones. While the primary use of the natural rubber isolation bearing remains in regions with high earthquake risk, its benefits are now being sought for protecting sensitive equipment within buildings, such as hospital operating theaters, data centers, and precision manufacturing facilities. Furthermore, the natural rubber isolation bearing is being specified for bridges and overpasses to mitigate the effects of traffic vibration and thermal expansion, thereby extending the service life of these critical infrastructure assets. The versatility of the natural rubber isolation bearing makes it a valuable solution for a wide range of vibration challenges.

Research and development efforts continue to refine the capabilities of the natural rubber isolation bearing. Engineers are exploring new compound formulas to enhance damping properties and improve long-term aging characteristics. There is also a growing interest in developing standardized testing protocols and design guidelines to make this technology more accessible for a broader range of projects. As urban density increases and the built environment faces more complex challenges, the role of the natural rubber isolation bearing in ensuring structural integrity and occupant safety becomes ever more critical. This focus on innovation promises a future where structures are not just built to withstand forces, but are intelligently designed to isolate themselves from harm.