The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTEIn regions prone to seismic activity, a specialized engineering component is playing an increasingly vital role in safeguarding buildings, bridges, and critical infrastructure: the lead rubber bearing. This innovative isolation device is designed to absorb and dissipate the destructive energy of earthquakes, significantly reducing the forces transmitted to a structure above. The widespread adoption and proven performance of the lead rubber bearing represent a fundamental shift in seismic design philosophy, moving from rigid resistance to flexible isolation for enhanced resilience and safety.

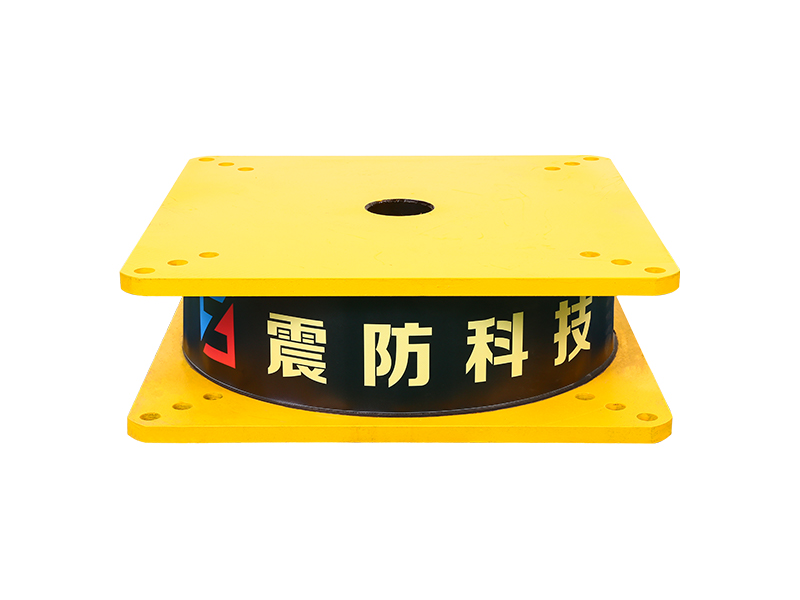

The lead rubber bearing is a type of base isolator, typically installed between a structure's foundation and its superstructure. Its construction is a composite of layered materials. At its core, alternating sheets of steel and natural rubber are bonded together to form a stiff yet flexible pad. This laminated rubber steel pad provides vertical stiffness to support the building's weight while allowing for substantial horizontal displacement. Embedded centrally within this pad is a solid cylindrical core of lead. This lead core is the critical energy-dissipating element of the lead rubber bearing. During an earthquake, as the bearing deforms, the lead core yields plastically, converting the kinetic energy of seismic motion into heat, thereby damping the vibrations and limiting the sway transferred to the structure.

The primary function of the lead rubber bearing is to decouple the building from the damaging horizontal motions of the ground. When seismic waves occur, the ground moves violently, but the lead rubber bearing allows the foundation to shift while the structure above moves more slowly and uniformly. This isolation effect, provided by the lead rubber bearing, can reduce the accelerations experienced by the building to a fraction of those in a fixed-base structure. This not only prevents catastrophic structural failure but also protects non-structural elements like ceilings, partitions, and sensitive equipment housed within, ensuring the building remains functional post-earthquake—a key consideration for hospitals, emergency response centers, and data facilities.

The application of lead rubber bearing technology is lots of prominent in the construction of new critical infrastructure and the seismic retrofit of existing historic or essential buildings. Engineers select and configure lead rubber bearings based on the specific weight, geometry, and required performance level of the structure. The design allows for predictable and reliable behavior; the rubber provides the restoring force to center the building after shaking stops, while the lead core delivers immediate damping from the onset of motion. This combination makes the lead rubber bearing a robust and passive solution, requiring no external power or active control systems to operate during a seismic event.

The role of the lead rubber bearing is set to expand as building codes in seismically active zones increasingly incorporate or mandate performance-based design principles that prioritize life safety and post-disaster functionality. The technology is also being considered for protecting other critical assets, such as nuclear facilities, airport control towers, and long-span bridges. As urban density increases in earthquake-prone areas, the implementation of seismic isolation systems centered on the lead rubber bearing offers a proven and effective strategy to mitigate risk. By allowing structures to weather seismic storms with small damage, this technology stands as a cornerstone of modern, resilient engineering, quietly bolstering society's defenses against one of nature's lots of powerful forces.