The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTEIn the ongoing pursuit of structural resilience, mechanical stability, and operational safety, a specialized class of components is proving indispensable: the metal damper. These devices are engineered to absorb and dissipate kinetic energy from dynamic forces, mitigating vibrations, shocks, and displacements. The strategic implementation of metal dampers is increasingly observed in fields ranging from civil engineering and seismic protection to precision machinery and transportation, underscoring their versatility and effectiveness in enhancing performance and durability.

The fundamental principle behind a metal damper is the controlled yielding of metallic materials. Unlike viscous or friction dampers, a metal damper utilizes the plastic deformation of metals such as mild steel, lead, or specially formulated alloys to convert mechanical energy into heat. As a force acts upon the device, specific metallic elements within the metal damper are designed to undergo yielding. This inelastic deformation is a highly repeatable and reliable process that absorbs a significant amount of energy, thereby reducing the amplitude of vibrations or the magnitude of forces transmitted to the primary structure or system. The behavior of a well-designed metal damper is predictable and stable, even under repeated loading cycles.

The application of metal dampers in civil engineering, particularly for seismic and wind engineering, is highly significant. Here, metal dampers are installed as part of a building's or bridge's lateral force-resisting system. During an earthquake or strong wind event, these dampers activate, absorbing a substantial portion of the seismic or vibrational energy that would otherwise stress the primary structural members. This protective action, facilitated by the metal damper, helps limit structural damage, reduces accelerations felt by occupants, and can be a key factor in allowing a building to remain functional after a major seismic event.

Beyond large-scale infrastructure, the metal damper serves critical functions in mechanical and industrial contexts. In automotive and rail transportation, various forms of metal dampers are integrated into suspension and chassis systems to absorb shocks from road irregularities, improving ride comfort and vehicle control. Within industrial machinery, a metal damper can be employed to suppress harmful vibrations in rotating equipment, presses, or forging hammers, protecting sensitive components and ensuring operational accuracy. The robust and often maintenance-free nature of a passive metal damper makes it suitable for these demanding environments.

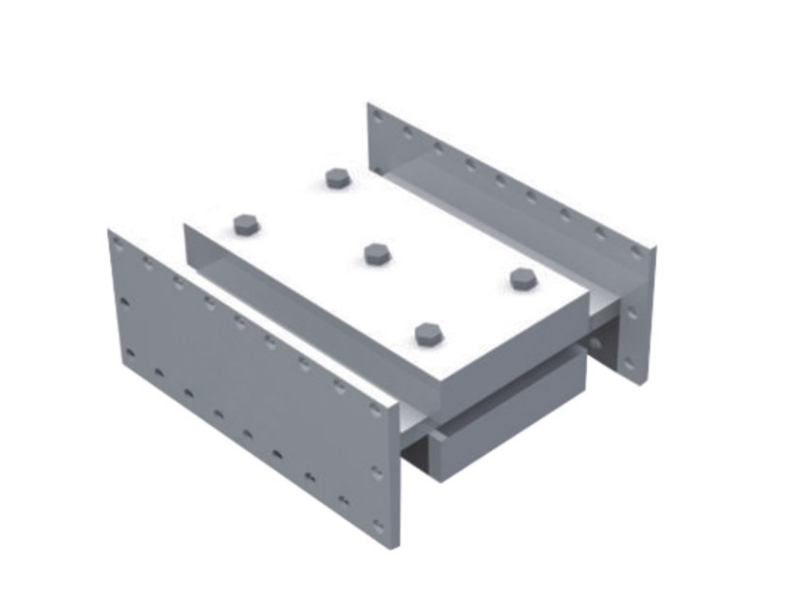

The design and metallurgy of a metal damper are tailored to its specific duty. Common types include steel plate dampers, which yield in shear or bending, and lead extrusion dampers, where lead is forced through a constriction. The geometric configuration is optimized to ensure a stable hysteretic loop—a measure of its energy dissipation capacity—and to promote uniform yielding. Engineers select materials and shapes to achieve desired performance characteristics, such as the initial stiffness, yield strength, and fatigue life of the metal damper.

The role of the metal damper is set to remain vital as resilience becomes a central tenet in engineering design. Their application may expand into new areas such as the protection of renewable energy infrastructure (like wind turbine towers) and sensitive equipment in data centers. The principle of using metallic yielding to safeguard structures and machinery represents a compelling blend of simple physics and sophisticated engineering. As dynamic loads from natural and operational sources continue to pose challenges, the reliable, predictable performance of the metal damper will ensure its continued status as a fundamental tool for managing energy and motion across a diverse industrial and construction landscape.