The company has been adhering to the corporate tenet of "quality first, customer first", and sincerely welcomes domestic and foreign customers to visit and guide.

GET A QUOTEThe field of earthquake engineering is witnessing a paradigm shift, driven by the widespread adoption and continuous innovation of the seismic isolation bearing. This transformative technology, strategically installed at the base of a structure, fundamentally alters how buildings and bridges respond to seismic activity. Rather than attempting to resist and withstand the full force of an earthquake, structures equipped with a seismic isolation bearing are effectively decoupled from the ground's violent shaking. This approach allows the ground to move independently while the superstructure above sways gently and remains largely undisturbed, thereby preserving its structural integrity and ensuring the safety of occupants.

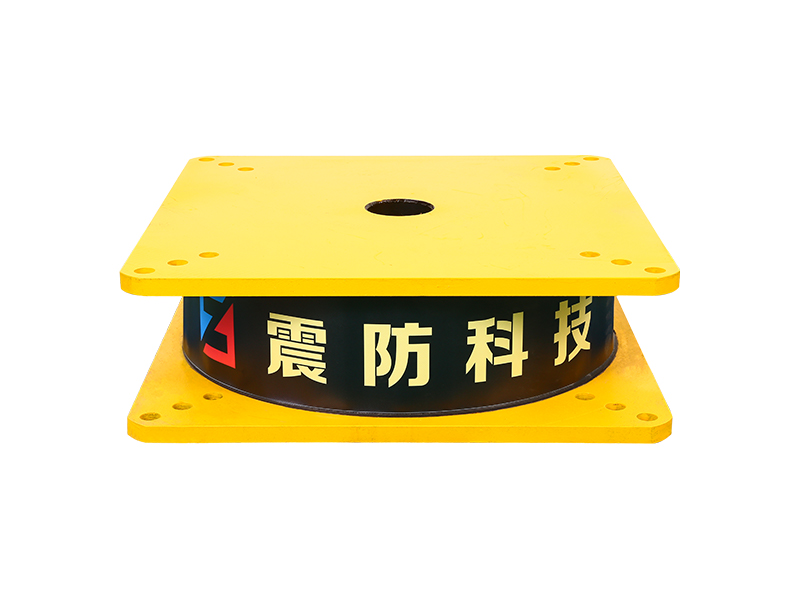

The core principle of the seismic isolation bearing is to introduce a flexible interface between a structure and its foundation. Typically composed of layered sheets of rubber and steel, the seismic isolation bearing possesses high vertical stiffness to support the building's weight, yet low horizontal stiffness to accommodate large lateral displacements. During a seismic event, the seismic isolation bearing deforms, elongating the natural period of the structure and dissipating a significant portion of the earthquake's energy. This mechanism drastically reduces the accelerations and forces transmitted to the building, protecting critical structural elements from damage. The reliability of this technology has been validated through extensive laboratory testing and observed performance in actual earthquakes.

The applications for this protective technology are vast and varied. The seismic isolation bearing is now a standard feature in the design of critical facilities such as hospitals, emergency response centers, and data hubs, where functionality must be maintained even after a major seismic event. Its use is also expanding in the retrofit of historic and older buildings, providing a viable solution to bring them up to modern safety standards without altering their architectural character. Furthermore, the seismic isolation bearing is indispensable for safeguarding complex infrastructure like highway overpasses, railway viaducts, and airport terminals, ensuring the continuity of transportation networks post-disaster.

Manufacturing a high-quality seismic isolation bearing is a precise engineering process that demands rigorous quality control. The compounding of the rubber is critical to achieving the desired elasticity, durability, and aging characteristics. The vulcanization process that bonds the rubber to the steel plates must create a permanent, inseparable laminate capable of sustaining repeated cycles of deformation. Each individual seismic isolation bearing undergoes prototype testing to verify its performance under simulated seismic loads, ensuring it meets or exceeds the stringent requirements set by international building codes.

Ongoing research is focused on enhancing the capabilities and expanding the possibilities of the seismic isolation bearing. Developments include the integration of advanced materials with higher damping properties and the exploration of adaptive systems that can tailor their response to the specific intensity of ground motion. The future points towards smarter isolation systems that can provide real-time data on their condition and performance. As urbanization continues in seismically active regions, the role of the seismic isolation bearing in creating resilient communities becomes increasingly vital. This technology stands as a cornerstone in the global effort to construct a built environment that can not only survive earthquakes but also recover from them quickly.